1. Choosing the Material

The journey begins with selecting the right fabric, which depends on the type of sport and the needs of the athlete.

Creating sportswear is an intricate process that combines functionality, comfort, and style. Here’s a comprehensive look at how different types of sportswear are made, from selecting the thread or cloth to the final piece.

Types of Fabrics:

- Polyester: Known for its moisture-wicking properties, durability, and flexibility.

- Nylon: Lightweight and resistant to abrasion, ideal for high-impact sports.

- Spandex (Lycra): Offers excellent stretch and shape retention, commonly used in activewear.

- Cotton: Breathable and comfortable, often used for casual sportswear.

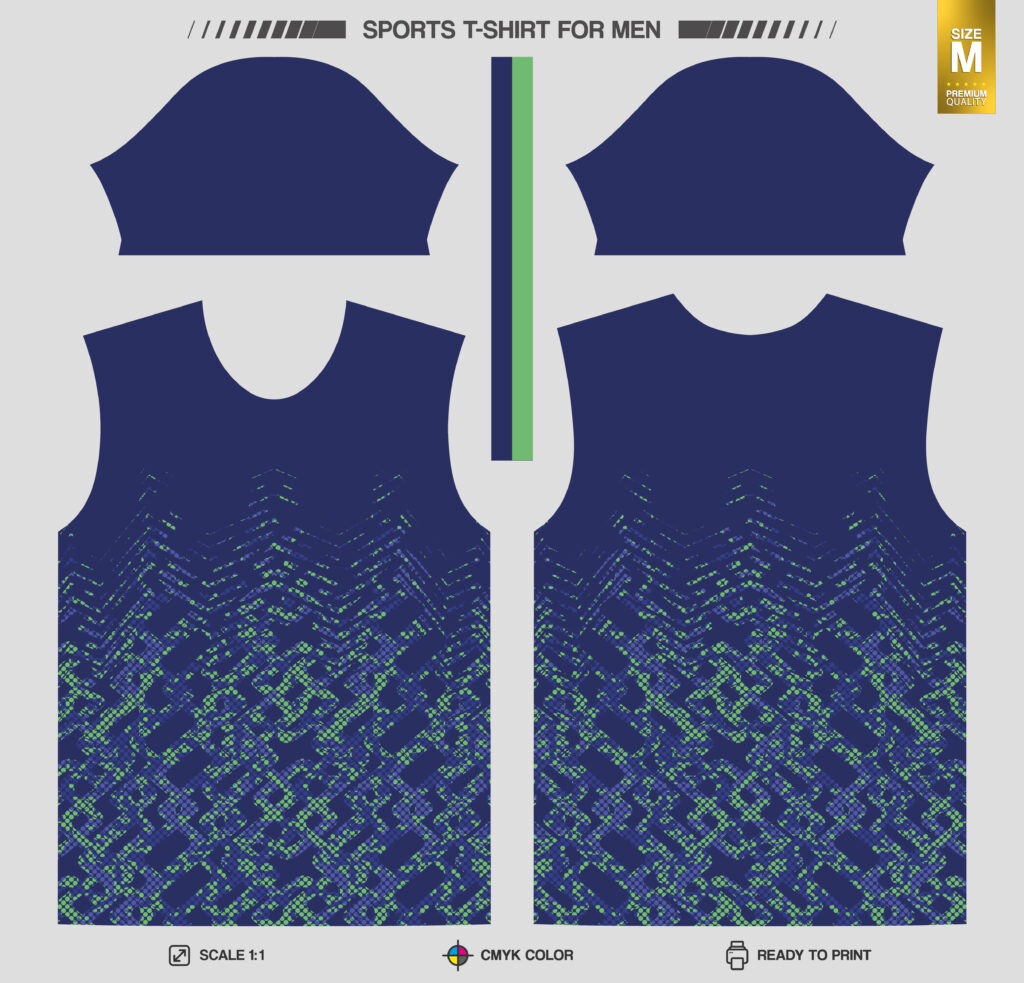

2. Designing and Pattern Making

Once the material is chosen, designers create patterns that determine the shape and fit of the sportswear.

Design Elements:

- Pattern Templates: These are outlines for cutting the fabric.

- Seam and Stitching Types: Different stitches for different needs, such as flat seams to prevent chafing.

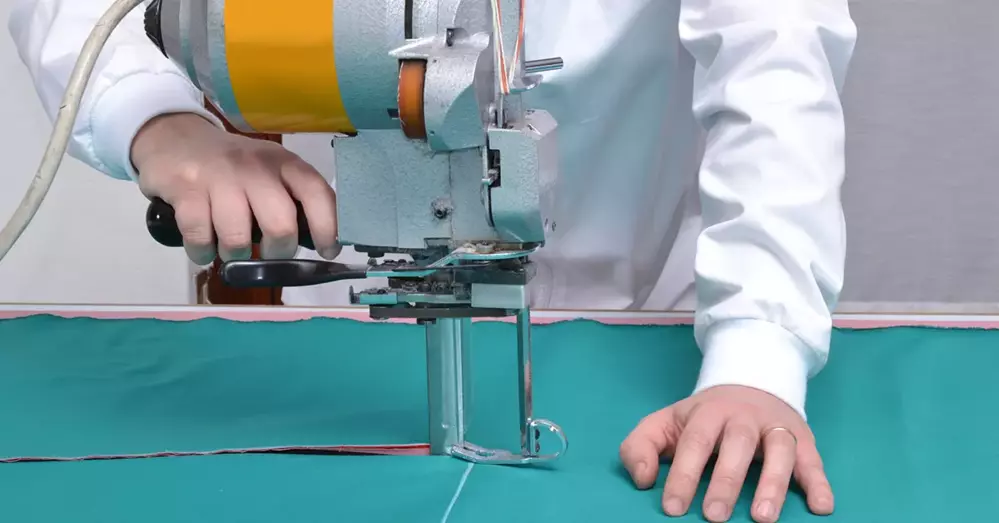

3. Cutting the Fabric

With the patterns ready, the next step is to cut the fabric according to the design specifications.

Cutting Techniques:

- Manual Cutting: Using scissors or rotary cutters for smaller runs.

- Automated Cutting Machines: For large-scale production, ensuring precision and efficiency.

4. Sewing and Assembling

The cut fabric pieces are then sewn together to create the final garment. This involves:

Sewing Techniques:

- Overlock Stitching: To prevent fraying and for added durability.

- Flatlock Stitching: For a smooth finish, reducing irritation against the skin.

5. Adding Functional Elements

Sportswear often includes additional features to enhance performance.

Features Include:

- Mesh Panels: For ventilation and breathability.

- Reflective Elements: For visibility in low-light conditions.

- Padding and Inserts: For extra comfort and protection.